The Nolsen strives to provide innovative support to its customers in the field of heat pump heating-cooling in building engineering.

The co-founder of Nolsen brand is Cool4U Systems Ltd., which has achieved many awards since estabilished in 2001, moreover, the company is exclusive distributor of the Gree air-conditioners and heat pumps’ in Hungary. The other co-founder of Nolsen is Easykit Ltd., which deals with planning and distributing of building engineering systems. Their main goal is to ensure a permanent high quality, price-value ratio and excellent service.

Our products include compact heat centers which can be adjusted to heat pump systems, as well as the Nolsen HomeControl, which provides a higher level in heat pump heating system control possibility for its users.

The Nolsen heat centers, together with their accessories, contain all the elements that are essential for heat pump heating of a residental house. In order to facilitate the installation process, our unit comes pre-assembled to the customer.

The compact heating center is an excellent choice both for heating modernization and for the construction of a new heat pump system, as well as for those who are new to the implementation of heat pump systems.

Regarding the details talk to one of our expert: Contact us

Nolsen – Pre-assembled compact heat center for heat pumps

HUNGARIAN INNOVATION ON THE MARKET

PRE-ASSEMBLED COMPACT HEAT CENTERS

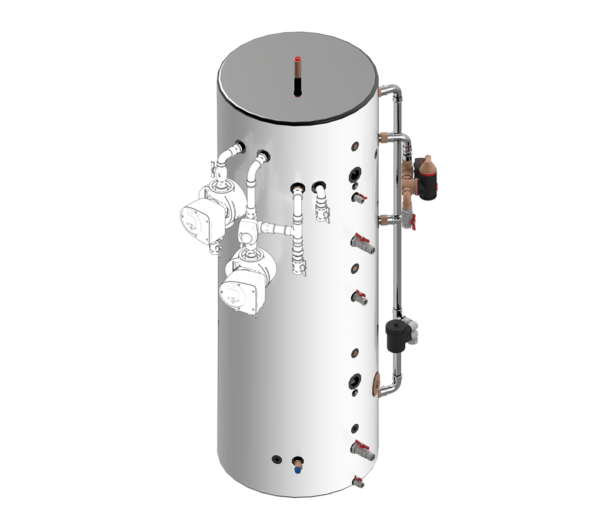

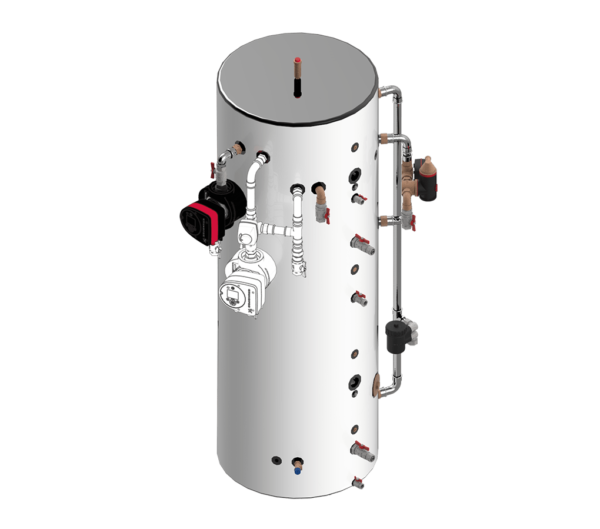

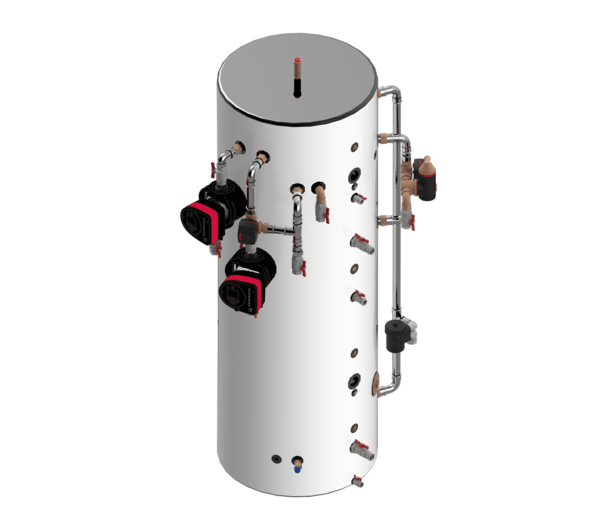

The product family which has just entered the market thanks to the cooperation of two Hungarian market players offers a reduction in the chance of construction issues, a small space requirement and quick work for heat pump systems. The heat centers equipped with all the necessary components and additional accessories (connectors, heat exchanger, magnetic filter, microbubble separator, mixing valve and circulation pump) can function as heating and cooling buffers or in combination with them, as domestic hot water storage, depending on their design.

In the first half of 2023, 18.2 percent, almost one billion cubic meters less natural gas was used in Hungary compared to the same period in 2022. Two-thirds of the saving is due to the – forced or conscious – savings of economic companies, and one-third can be attributed to the population. The reason is on the one hand, the milder than usual winter, but this does not explain the decline in consumption as a whole, because it also required investments that allowed households to “escape” from gas. One means for this is the heat pump, which, in addition to being a gas-independent heating option, is also suitable for cooling with suitable heat emitters. Read more...

Mistake behind mistake and the solution

The heat pump boom, which can also well perceived in the trade and is temporarily even accompanied by a shortage of goods, has also brought with it horror stories about all kinds of construction defects. There were many contractors who took advantage of the opportunity but lacked both the theoretical knowledge and confident professional experience required for the correct construction of heat pump heating systems. One of the focal points of the mistake is to be found in the improper design of the heat centers. Even if the heat source works perfectly in theory, according to the factory parameters, and the heat emitter side is well sized and constructed, if something goes wrong between the two.

Pre-assembled heat centers

The risk of construction mistakes is significantly reduced if we use a complex, pre-assembled heat center specifically designed for heat pump heating/cooling or, on demand, DHW production. These systems are already known on the market of traditional heating and hot water production solutions, several – mostly foreign – manufacturers offer them. Now, such a product line has appeared on the heat pump market as well, thanks to the cooperation of the Hungarian representative office of the world’s largest residential air conditioner manufacturer and a Hungarian company offering complex building engineering systems – design, pre-assemble, delivery. Let’s see how they are built and what are these pre-assembled ‘cylinders’, i.e. heat centers, are for.

Combined tank

The Nolsen HWT-500 stainless steel combined tank is equipped with a bottom placed DHW tank with a 4.5 m2 surface ribbed pipe spiral heat exchanger with a gross capacity of 400 liters and an 80 liter stainless cooling/heating buffer tank above it. The combined storage is surrounded by vapor barrier insulation.

The upper buffer and the lower domestic hot water tank are separated from each other without a thermal bridge. The storage tank made of stainless steel (DHW SUS316, buffer SUS304) is designed to meet the highest demands, even in industrial systems, but can also be installed in the case of aggressive medium. The size and position of the connectors on the buffer tank are designed to be ideal for heat pump heating/cooling systems.

Among the heat center components, the magnetic dirt separator provides continuous protection to the heat pump and all elements of the heating system against the harmful effects of black iron oxide sludge and non-magnetizable debris.

The microbubble separator completely separates the gases (air) from the liquid flowing in the heating/cooling system during a special process. Among its advantages is that even the smallest microbubbles adhere to the PALL rings in the microbubble separator and separate from the liquid. Thanks to the cone-shaped air chamber, the largest possible distance can be maintained between the liquid level and the vent valve, thus ensuring adequate air separation.

In the heat center, switching between the heating buffer tank and domestic hot water storage is ensured by a copper three-way changeover valve and the associated rotary actuator.

Simple tank for cooling and heating

The main unit of the heat center is a 80-liter, insulated, stainless steel buffer tank, which was specially developed for a heat pump heating/cooling system.

Its elements:

- 80 liter buffer tank made of stainless steel (SUS304)

- 35 mm stainless pre-assembled pipe system

- microbubble separator

- magnetic dirt separator

- change-over valve and associated rotary actuator

- 5/4 ball valves

- automatic air vent

- safety valve group

It can be ordered with either a mixed circuit, a direct circuit or even both, as well as a mixing valve and circulator.

Control, regulation

The control is provided by a device that has been developed for the heat pump family exclusively matched to the heating center. It covers all the basic functions that may be needed for an automation: it ensures the power supply of the bus, the connection with other connected devices (heating and cooling units, thermostats), and enables remote control from a computer, smartphone or tablet. At least one controller is required per installation.

The module includes all functions, external software is not required, and programming can be done through the web browser, with easy-to-select drop-down menus. The module allows for very simple installation, only basic electrical knowledge is required for installation and programming. The device can be mounted on a DIN rail, in an electrical distribution cabinet (standard distribution board).

The most important solution of the controller which makes the different from the products of other manufacturers is that there is no central device, i.e. each device is a central device and also an extension, which enables very high error tolerance. In the event of a failure only the function that was controlled by the faulty device is lost, there is no complete loss of function. Modul has built-in software for programming the device’s functions and controlling the device and peripherals.

Functions:

- connected to modbus thermostats or 1-Wire temperature sensors, cascade control of one or more heat sources with start & stop signal or modbus;

- zone control for surface heating and cooling with dew point water temperature control, independent, manual or scheduled room temperature and humidity control for the highest possible comfort and energy efficiency.

Summary

The pre-assembled heat pump heating center contains all components for proper operation and very quick installation. It takes up small space, and thanks to its complexity, it shortens the time of installation work and reduces the chance of committing installation mistakes. It can be used for heating and cooling systems with a power of 4-16 kW, as well as for the preparation and storage of domestic hot water as required.

The installation is exceptionally simple

The pre-assembled Nolsen heat center contains all the necessary components, the installation and assembly is simple and quick so the heating and cooling system can be ready to use within a very short time.

Nolsen products

Unique technology in the field of heat pump heating systems. The pre-assembled heat centers in the Nolsen product range and the Nolsen HomeControl have been specially developed for heat pump systems, thereby supporting the quality and speed of installation.